Frequently Asked Questions

Screen Printing Machines

How to extend the life of your halogen lamps?

How to install and Set Up the Machine?

What are the RapidTag Features and Functions?

How many impressions can it do per hour?

What is the typical maintenance on these machines?

Does this machine require air?

Is the image really cured after the product comes out of the machine?

Sampling

YES, SAMPLE TESTING can be done. If you are interested in our equipment and want to see if your product can be printed on then please follow these directions and let us work with you to make your production more efficient.

First, send us at least a dozen (or more if possible) samples of the product that you’d like to print on and the ink you want to print with.

Next, give us the logo, name, design, whatever it is that you’d like to have printed on the item.

That’s all YOU need to do. Once we have your samples WE will;

Set up your products for printing and print them.

Take a video of the entire process so that you can see EXACTLY how we did it, including any modifications we made to the ASPE LP1 and/or ASPE LP2 for your product.

Send your samples and the custom video back to you for your evaluation.

This is a FREE service that we will provide to serious customers to prove that the RapidTag is the best screen printing machine available today.

Customize Machine

YES, we do customized machines, as you can see under Many More Screen Printing Options. Let us know what you need, a bigger print area, different products to print on, read more on the CUSTOMIZATION PROCESS, and use the contact form to let us know.

YES, there are Finance Options:

100% Financing including soft costs (shipping, accessories, etc.)

No Down Payments Required

Deferred & Seasonal Payments

Tax advantages via IRS Section 179

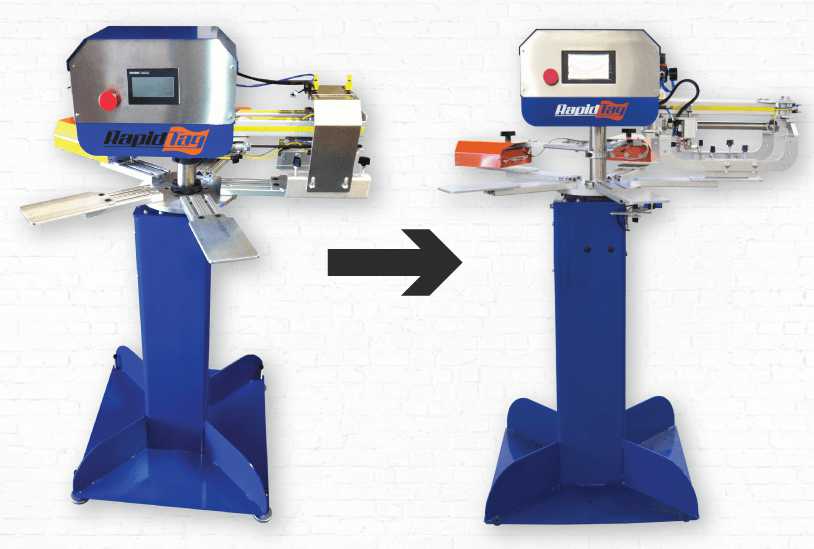

Refurbishing a ASPE Screen Printing Machine, means:

At ASPE Inc. we are constantly making improvements to the RapidTag screen printing machines. These updates can vary from a newer PLC to improved pallets.

If you already own a RapidTag and would like to update your machine to the latest model, please contact us to discuss the details and possibilities.

Extend the life of your halogen lamps.

How to – To extend the life of your halogen Flash Cure lamps, this will explain it for you.

Impressions can it do per hour

It all depends on you and / or your operators. For tag-less tee shirts the average is about 1000-1500. Least we have seen is about 700 per hour and the most we have seen is 2150 per hour. For promotional products it is much easier to load so this means they are averaging over 1350.

Am I responsible for Customs and Duty Charges?

Yes. Customs and duties are implemented by your government when products are imported into your country. These charges are out of ASPE Inc. control.

Does this machine require air?

Yes, our machines print heads all require about 90-110 psi, dry air. Each machine does no more than 3 cfm. For exact information please see product page. The indexing system is all electric.

Crating cost

Vary due to size and specs of the machine, standard machine crating starts at $300.00

Delivery Time

After receiving the down payment, please allow 4-6 weeks to manufacture your machine. For Rush Orders, there will be additional charges depending on how soon you need the machine. For more information contact your ASPE dealer or representative.

Warranty

All standard machines come with a 2-yr limited warranty on non-consumable parts. For more information, please see Warranty & Return Policy page.

Can you operate this machine with one operator?

Yes, we actually have printers that are doing this and they are still doing 600-1000 per hour.

Curing

For tag-less t-shirts, most plastisol inks will last about 10-15 industrial washes. We suggest printing the tags first and then the front of the shirt afterward, that way the t-shirt only goes through the dryer once. The option is low cure ink to, for delicate color, like white on black. Or water-based ink, with a cold-cure catalysator.

Maintenance on machine

Light bulbs will last you 2000 hours. You want to put high-temperature red grease in the gears every 3-4 months. Also, keep track of pneumatic tool oil in the lubricator.

Print on Plastic

Yes, we will make the machine so it will print and cure UV inks. This is considered a custom job.

Print Area

Your max print size is 6 x 6 inches for a standard RapidTag machine. The XL series has a max print area of 10 x 10 inches. YOU need larger, let us know, we do! Contact us

Special Machines

Besides mini auto screen printers, we are in the process of making a few other game-changing machines that are projected to start selling sometime in 2015 (we are in the testing stages). We have also made many customized machines for various different industries and applications.

Business hours

We are open Monday – Friday, 8 am – 5 pm Pacific Time(PT)

International Africa, Asia, Europe, Monday – Friday, 8 am – 5 pm, +4 Greenwich Mean Time (GMT)