RapidTag Three Colors Small Tagless Label Printing Machines

Multi-headed machine for three-color printing, normally used for printing on tote bags or sleeve prints. With the ability to print specialty applications such as high density or under-basing for darker garments. Remember that each print head gets its own flash cure system, so you’ll never accidentally print wet ink over wet ink

SPECIFICATION

Height: 55“ | 140cm

Diameter: 38″ | 97cm

8x Stations

3x Print Heads

3x High-Density Flash Cure Units

Print/Flash/Print/Flash/Print/Flash

Standard Pallet Size 4″ Wide x 8 ” Long | 10 cm x 20 cm

Max Image Print Area 6″ Wide x 6″ Long | 15 cm x 15 cm

Standard Frame Size 9″ x 14″ | 22 cm x 35.5 cm

Flash Cure Size 5″ x 5″ | 12.7 cm x 12.7 cm

KEY FEATURES

- Parts Counter

- Stroke adjustment

- Micro Registration

- Index Speed Set up

- Stepper Motor Indexer

- Adjustable stroke length

- Squeegee Angle Adjustment

- Parts Sensor (no product no print)

- Adjustable Stroke and flood speed

- Print Accuracy of .001″ | 0.02mm

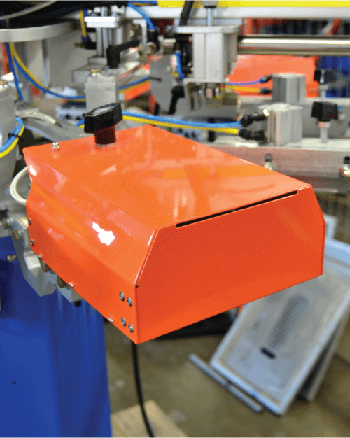

- High-Density Flash Cure Units

- Pneumatic Screen Locks

- Color Touch Screen

- Curing Time Set up

- Hoodie arms

- Dwell set up

Add-ons

Pallet Options: Socks, Sleeve, Face-Mask, Swimming Caps, Gloves Printer, Can Cooler.

Laser guidance to assist positioning

Foot Pedal

Unloader

This machine can be adapted for various applications

Specify which pallet size you need

We give!

FLASH CURES

Every print head comes with its own flash cure so you do not have to print wet on wet. This allows the operators to continue production without having to worry about build-up on the next screen.

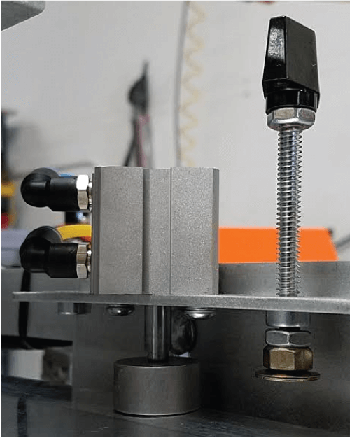

STROKE ADJUSTMENT

Adjust your stroke length according to the size of your image. This also helps speed up production.

SQUEEGEE ANGLE

Adjust your squeegee angle and control your squeegee flexing accordingly to print on all different types of substrates with a variety of different inks.

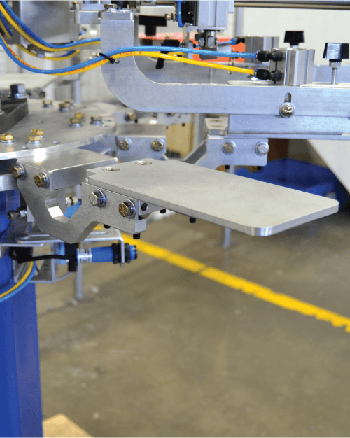

MOTION SENSOR

Also known as the “parts present sensor”, it detects your product and tells the machine to print on the given pallet. If there is no product present on the pallet then the RapidTag will NOT print.

PNEUMATIC SCREEN LOCK

The automatic screen airlocks allow the user to quickly fasten.

HOODIE ARMS

The hoodie arms definitely come in handy when you have a hoodie job to do. Easily place the hood of the hoodie in the cavity in order to not disturb the rest of the machine during production.

What Required on a Tagless Label

Please understand that most of these requirements are only for products that are being shipped to different countries in high volumes.

Size

When shopping, consumers often check the neck label to confirm they are getting the correct size before purchasing the garment. Feature the size of the garment clearly for the consumer to see. It will often be the first thing they look for when checking the label

Fiber/ Material Content

For legal and customs purposes, you must list the fiber content of the garment. This is mostly important if you are planning to sell your garments internationally. List in descending order the percentages by weight of each fiber in the product accompanied by the generic fiber name.

For example: 100% Cotton, 90%/10% cotton/polyester, 50/25/25 polyester/ringspun USA cotton/rayon

Country of Origin

This is also important for customs purposes. Often, garment decorators are faced with products made elsewhere so they must specify where the product is made. They can also state where the product was printed/ decorated.

For Example: Made in Bangladesh / Printed in USA

Manufacturers Identity

Whoever is handling the product, garment labels must identify either a company name or RIN number. This must be included when you are shipping the product(s) to another country.

Washing/ Care Instructions

You will often see garment manufacturers and decorators put care symbols to inform the consumer how to wash the garment. Sometimes, instead of symbols, the washing instructions will be printed in text right on the label. These symbols or instructions are not required but are nice pieces of information.

REQUIREMENTS

AIR

Clean Dry Air

90-110 PSI

1.6 CFM

6-8 Bar

45L/min

POWER

220 Volt

Single Phase

25 Amps

Our Product Video

SHIPPING INFORMATION

Domestic Class 175

420 lbs | 190 kg shipping weight

Crate size 49″ x 49″ x 62″ (61″ on request)| 125 cm x 125 cm x 158 cm (155cm on request)

International Shipments are all heat-treated/ISPM 15 certified