Socks Screen Printing Machine

Screen printing is the most popular way to decorate ceramic, metal, plastic, paper, and other materials. This process also applies to socks for the production of Non-Slip Socks.

This type of socks is worn by patients at hospitals, visitors at trampoline parks, and kids that want to take corners a little bit too quickly.

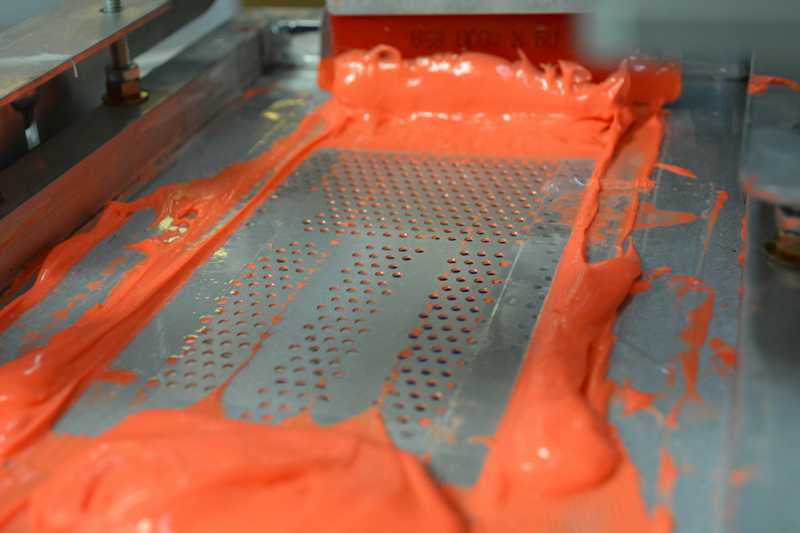

As you can see we are not using traditional mesh, instead we are using a perforated metal screen. This process of printing on socks is similar to high-density screen printing, but instead of having to stack up the image with traditional mesh, our clients are easily able to do a single stroke and then move on to the next garment. Our sock screen printing machine is based on the LP-Serie. Basically, you can print socks with any of our machines, because they are simply specially-designed pallets that fit on any of our machines. Screen printing socks couldn’t be easier.

Once the screen is made is just a matter of having the correct ink solution to apply to the socks. In this application, the inks are usually PVC or silicone-based.

NON-SLIP / GRIP SOCKS

We used silicone gel to print these socks. We also put on a thicker coat of emulsion on the screen (110 mesh). We used two screens for this particular application. The first screen was for the under-base plastisol black….and the second screen was the black silicone gel ink. Our high-density dryers cured the ink immediately. This makes production and lead times much faster.

SPECIFICATIONS TABLE

Substrate: Cotton, wool, nylon, polyester, or spandex

Speed: 1000-2000 pcs per hour

Finish: High-density print, the sticky grip texture, nonslip

Pallet Adhesive: Not Needed but some customers use some

Mesh: Low Mesh 60-80 (or steal screen plate)

Emulsion: Capillary Film (or steel screen plate)

Similar Application(s): None

Special Instructions: Speak with a representative to learn about correct printing ink to use for nonslip printing