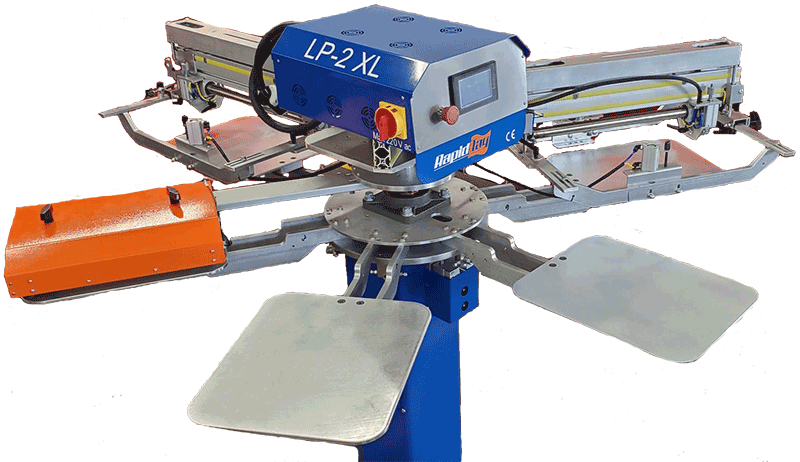

Two Colors Large Automatic RapidTag Screen Printing Machines

The LP2 XL was originally designed for screen printing on promotional tote bags, which are one of the most popular promotional

products. The LP2 XL has the largest print area out of all the RapidTags and it offers the lowest cost per print along with the highest throughput.

SPECIFICATION

Height: 55“ | 140cm

Diameter: 67″ | 170cm

6x Stations

2x Print Heads

2x High-Density Flash Cure Units

Print/Flash/Print/Flash

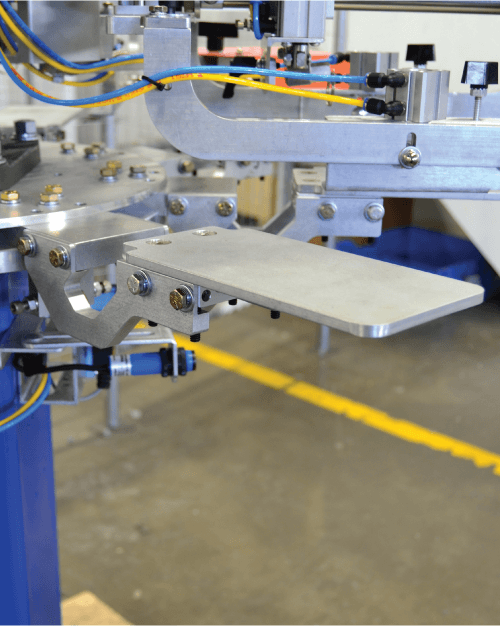

Standard Pallet Size 13.25″ Wide x 16 ” Long | 33.6 x 40.6 cm

Max Image Print Area 12″ x 12″ | 30.48 cm x 30.48 cm

Standard Frame Size 16″ x 20″ | 40.6 cm x 50.8 cm

Flash Cure Size 12″ x 12″ | 30.48 cm x 30.48 cm

KEY FEATURES

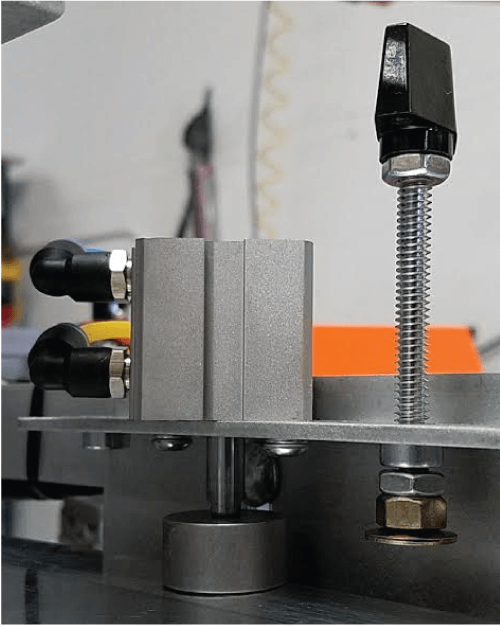

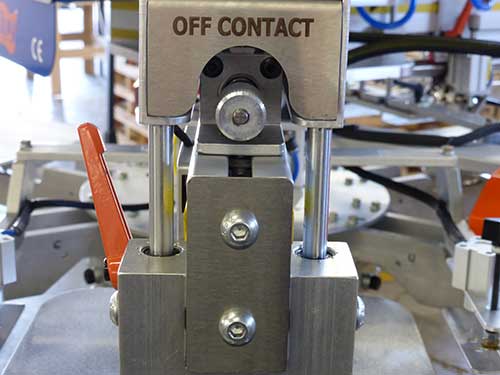

- Dwell set up

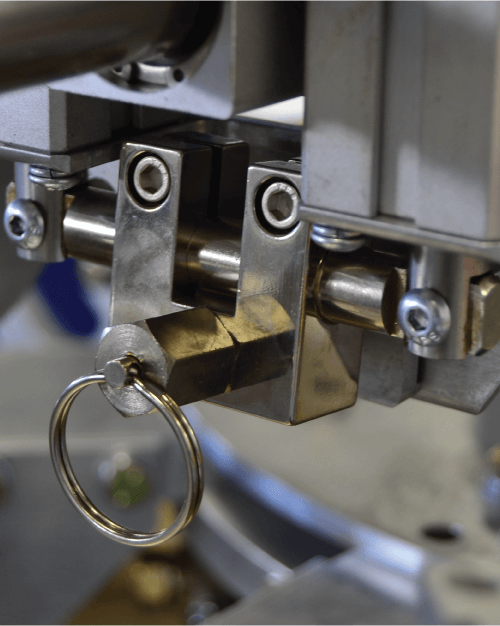

- Micro Registration

- Index Speed Set up

- Stepper Motor Indexer

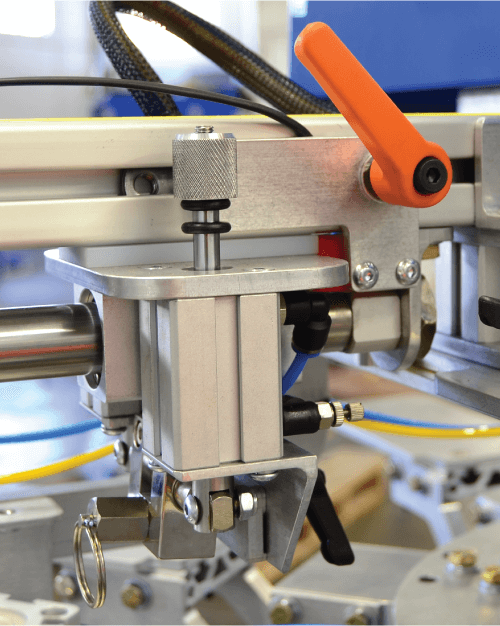

- Squeegee Angle Adjustment

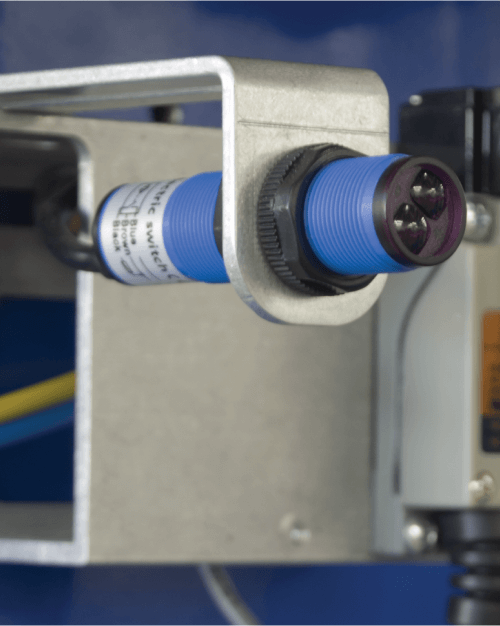

- Parts Sensor (no product no print)

- Adjustable Stroke and flood speed

- Print Accuracy of .001″ | 0.02mm

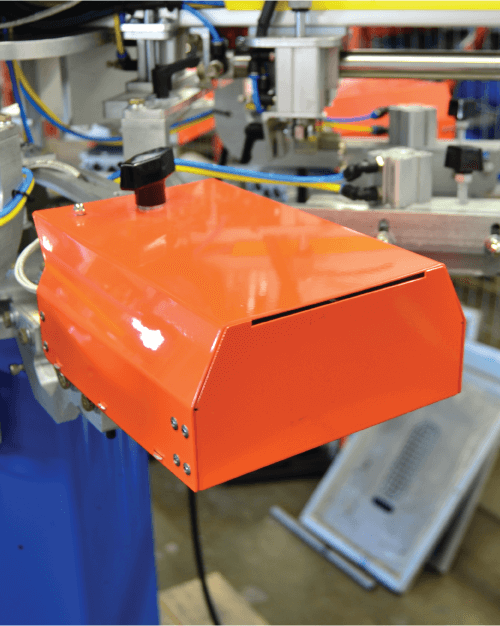

- High-Density Flash Cure Units

- Adjustable stroke length

- Pneumatic Screen Locks

- Color Touch Screen

- Curing Time Set up

- Stroke adjustment

- Parts Counter

- Hoodie arms

Add-ons

Pallet Options: Socks, Sleeve, Face-Mask, Swimming Caps, Gloves Printing, Can Cooler, Kids size.

Laser guidance to assist positioning

Foot Pedal

Customized larger printing area, possible

The machine can be customized for different application

We Give!

REQUIREMENTS

AIR

Clean Dry Air

90-110 PSI

1.65 CFM

6-8 Bar

47L/min

POWER

220 Volt

Single Phase

50 amps

Our Product Video

SHIPPING INFORMATION

Domestic Class 175

580 lbs | 263 kg shipping weight

Crate size 71″ x 71″ x 62.5″ (61″ on request) | 180 x 180 x 159 cm (155cm on request)

International Shipments are all heat-treated/ISPM 15 certified