When it comes to garment decorating, there are a number of different directions that you could choose. When selling your own clothes, you need to be aware of the benefits and drawbacks of all the different ways to decorate fabric, so you can get the job done efficiently, to a high standard of quality, and in a cost-effective manner.

We’ve put together this blog comparing five distinct decorative techniques for garment production, so you can approach manufacturing in the way that works best for your business.

Garment Decorating Technique #1 – Embroidery:

Embroidery has been a part of garment decoration for thousands of years, with its roots in China going as far back as 30,000 BC, and it’s still being used today. Embroidery is the act of sewing logos, images, and graphics directly into the garments, and can give them a nice textured look. There are two main forms of embroidery, with flat embroidery being slightly more simple and sparse, while 3D puff embroidery is used to create more three-dimensional designs by using a layer of foam to puff them out.

Along with this, embroidery allows you to utilize a number of different colors and shapes, generally for no extra cost when compared to the flat rate. The logos and designs will be very long-lasting on the product; however, the process of embroidery can take some time and the flat rate is quite expensive, so it might not be the most effective method for larger manufacturing projects.

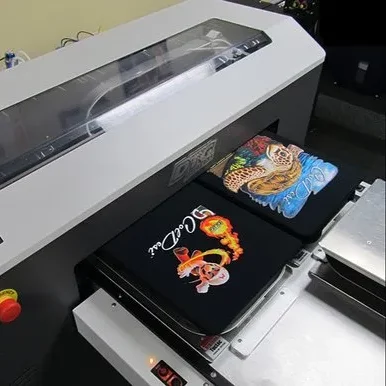

Garment Decorating Technique #2 – Digital Printing:

Digital printing is one of the more modern methods used in clothes decoration, with designs developed and analyzed on computers before being adapted into formats and inks that can be printed directly onto fabrics. It’s actually closer to the kind of printing you see from Xerox machines than any of the other methods.

Digital printing is a good choice for printing intricate and complex designs directly onto fabrics, giving the end result in a crisp and clean look. It’s also very fast and time-efficient.

However, if the ink isn’t properly absorbed by the fabric, you can expect to see some cracks or imperfections in the design, while the colors may not perfectly match what you designed on your computer. It’s also expensive for mass production, so may not be the best choice for a larger project.

Garment Decoration Technique #3 – Heat Transfer:

Heat transfer is one of the cheaper methods of garment decoration, particularly in the case of smaller quantities of clothing. It essentially works by the designer printing out their design onto a type of paper or vinyl, then pressing it hard onto the fabric, leaving behind the design. It’s considered a good choice for intricate or complicated designs, as well as personalized photo t-shirts, as you can essentially print any design directly onto the garment.

Along with resulting in photo-realistic designs for t-shirts and fabrics, it’s also fairly cheap to set up, and a clean, eco-friendly method. However, with all these benefits, there are some drawbacks in terms of the quality of the end result.

Heat transfer isn’t a suitable choice for darker materials, while this method also results in the fabric having a firmer, less natural feel. The designs are also not the longest-lasting, so the garments wouldn’t be considered premium products.

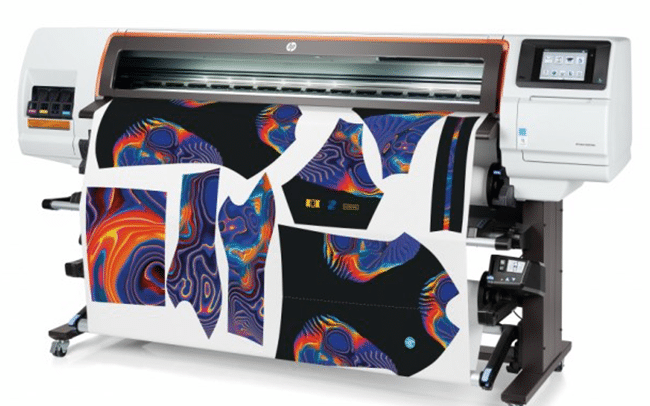

Garment Decoration Technique #4 – Dye Sublimation:

Dye sublimation is another newer method that can be used to decorate a shirt or any other garment, being one of the most scientifically savvy choices on this list. The process of sublimation is basically applying a special dye to a piece of transfer paper, then pressing it onto the garment with so much heat that the dye turns into a gas and chemically bonds directly into the fabric.

This method is great for producing high-quality designs with multiple colors, along with being the longest-lasting form of printing on this list, with a fairly short pressing time. However, dye sublimation can generally only be used on white or lighter t-shirts and is totally inapplicable to natural fibers like cotton and working only on polyester, a less eco-friendly material. It’s also not very cost-efficient when it comes to high-quantity orders and costs a lot to set up.

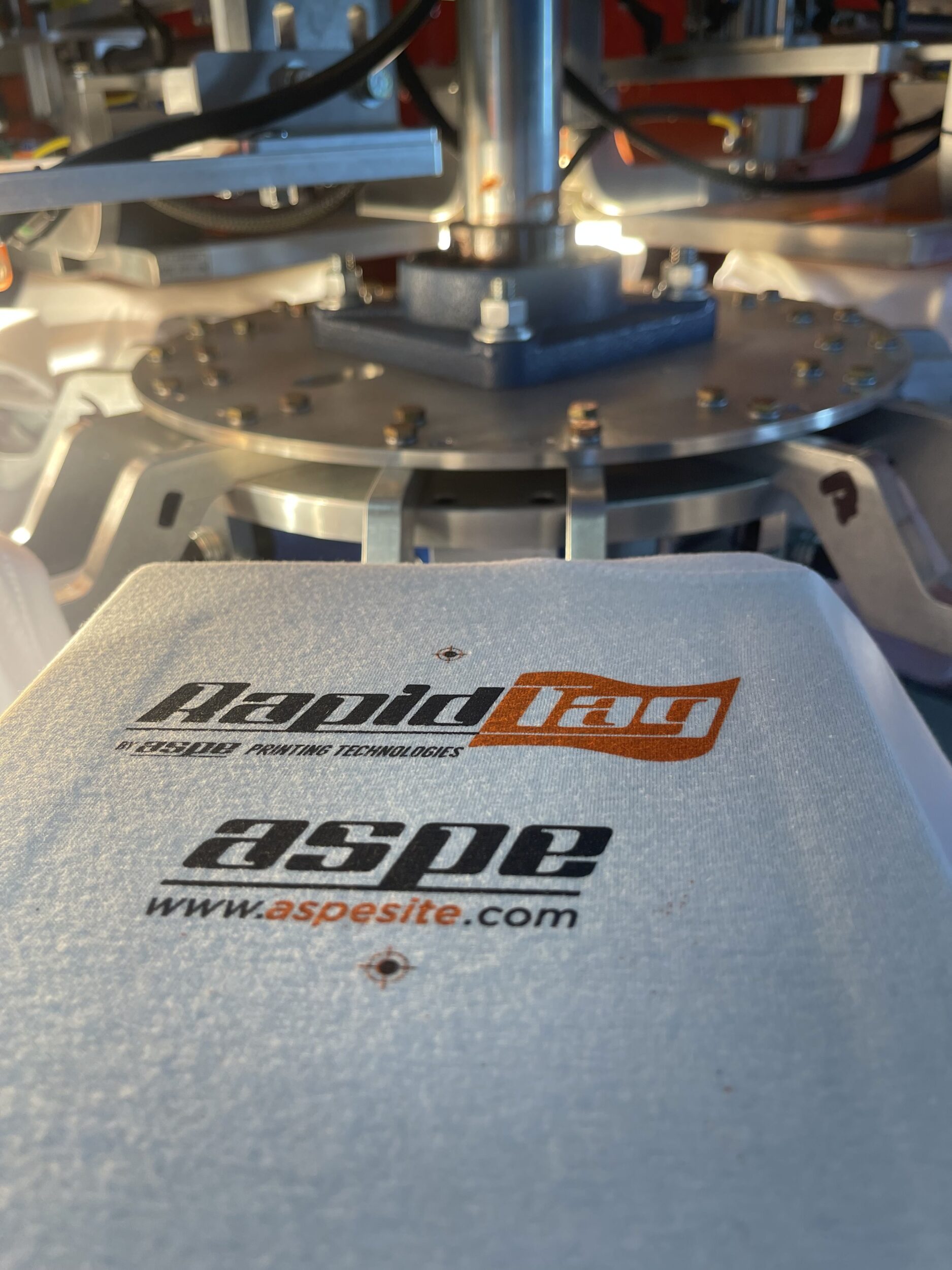

Garment Decoration Technique #5 – Screen Printing Machine

Using a screen printing machine is an excellent way to apply bold, simple statement designs to shirts and other garments. The method is essentially completed by squeegeeing thick inks through stencils one color at a time onto clothes, then heat curing them in place. It makes for clear, long-lasting designs that feel naturally soft when adhering to the fabric, perfect for logos and simple designs.

It doesn’t work particularly well for designs with many colors and costs a fair amount to set up; however, once you’ve got a bold contrasting design made, it’s a very cost-effective method for making batches and batches of the same design. You can simply use the same stencils time and time again. Along with this, screen print transfers can be applied to all shades of fabric, so you can utilize your design in different ways.

Final Thoughts

Before you choose your garment decoration method, you have to consider what you need it for. If you’re making a limited number of items, embroidery or dye sublimation might be the right choice for you. However, if you’re planning on applying logos to a wide variety of t-shirt colors and other garments, screen printing is the option you need.

If you’re interested in screen printing for your brand, visit Rapid Tag by ASPE today! We have a range of amazing screen printing machines ready to elevate your garments.