When it comes to adorning your t-shirts, pants, linens, or other garments with tagless labels, there’s one major battle that manufacturers have to consider – screen printing vs pad printing technology. Each of these methods has its own benefits and drawbacks when it comes to production time, setup cost, material cost, and the quality of the finished product.

We’ve put together this blog to explain the differences between using a RapidTag Screen Printing Machine or a pad print machine to impart tagless labels, and indeed other images onto garments.

What Is Screen Printing?

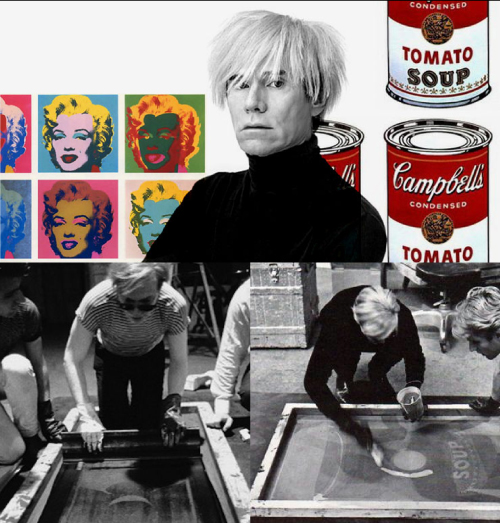

Before we get into the nitty-gritty of the Rapid Tag machine, we’re going to give a quick screen printing definition. Screen printing is the process of applying images to garments through the use of prepared screens or stencils, with ink passed through using a squeegee. The screens have to be used one at a time according to color to create the full image, then the ink has to cure, leaving the image or tagless label on the fabric.

It’s a centuries-old technique that was actually the method used by Andy Warhol for many of his most iconic designs!

What Is Pad Printing?

Pad printing is actually a form of stamping, with ink transferred from a silicon pad directly onto the fabric, then allowed to dry. A machine will hold the garment and the pad steady; the pad will be pressed into an ink plate that’s been designed with the logo, artwork, or label, then pressed to the garment.

Pad printing in its most basic form has been around for a very long time, however, the first pad printing machines only became available from manufacturers in around 1985, making it a fairly modern printing solution.

RapidTag Screen Printing vs Pad Printing: Cost

One of the most important things to consider when purchasing the technology for your business is the cost, both setup, and maintenance. When it comes to buying the initial technology, you can expect the machines to cost similar amounts, while some might argue that screen printing machines are generally a little bit more expensive.

The setup is the least of your worries, however, if running a business, as it’s an investment in your future. What’s more important is the costs moving forward, in terms of running the machines and paying for the ink.

In general, you can expect to find screen printing ink at fairly inexpensive prices, while it also has a very long shelf life, so stocks can come in handy. On the other hand, your pad printing cost for ink is usually significantly more expensive, and with a shorter shelf life, meaning you can’t keep as much on standby. Similarly, creating the screens you use to impart your images is generally a lot cheaper than it is creating the ink plates used to create the images in pad printing.

RapidTag Screen Printing vs Pad Printing: Process

Much like cost, you have to consider the actual working process of using either of these methods, with things like space and production time being massive factors that will affect your business.

It is true that pad printing machines are generally smaller than screen printing machines, however, this also limits the potential size of images and labels that you print onto your garments. A RapidTag Screen Printing Machine is designed for mass production, which is why it takes up a little more space, but this suits a more rigorous production schedule. You might need a more spacious work area, but the device itself offers more versatility in terms of image size.

Similarly, you have to consider how easy and quick the processes are. Pad printing is a relatively easy process once the ink plate has been crafted (which can take some time), however, it does take a fairly long time. Opposingly, one of the advantages of screen printing is how quickly it can be performed, especially with a RapidTag machine that is already accustomed to dealing with your prepared screens.

Rapid Tag Screen Printing vs Pad Printing: Images

Arguably the most important aspect of choosing your printing device is the quality and range of images that you can print onto your garments, which is especially crucial in the case of tagless labels. It’s worth noting that both screen and pad printing has to be done with one color at a time, with neither being adept at transplanting multicolored images in one go.

In terms of intricacy, pad printing does have a slight advantage over screen printing, as the ink plates can be made with fairly complex designs prior to the actual printing. However, with this added complexity, you’re sacrificing the ability to print larger images. Screen printing is better for producing a variety of sized images from small to large, but due to the screening process, the images will generally look better in simpler, more blocky styles.

When it comes to the quality of the final image, screen printing is known for creating some of the clearest images, with a really good level of opacity, looking clear and natural on the fabric. Pad printing is generally a little less consistent, producing less opaque, clear-cut images on fabric.

Final Thoughts

When it comes to printing tagless labels or any other images on garments, you can of course go in a number of different directions, but we feel that the RapidTag Screen Printing Machine is the best option. While ink pad printing is good for printing three-dimensional products and for smaller, more complex designs, you’re likely to be more consistently satisfied by the results of screen printing on a garment, while also saving money and time in the long run.

For more information on RapidTag Screen Printing Machines visit our website now!